Using radar to detect foreign objects in food

If foreign objects such as glass fragments get into food, it poses a major risk. The established X-ray techniques mainly detect metals – glass, plastics, and wood are a challenge. Therefore, radar systems are an ideal complement: The SAMMI® prototype has already successfully detected glass fragments in sandwich cookies and missing pieces of chocolate in Advent calendars.

Time and again, food has to be recalled because glass fragments, metal chips, wood splinters or plastic parts accidently ended up inside. While manufacturers do inspect their products for these foreign objects using X-ray devices, these procedures have their difficulties with plastics, wood, and glass. Millimeter waves can close this gap and optimally complement the established X-ray procedure. Even though the radar signal cannot scan metals like tinfoil – where X-ray beams are suitable – it is capable of reliably detecting other foreign objects. In addition, it doesn't pose any health risks.

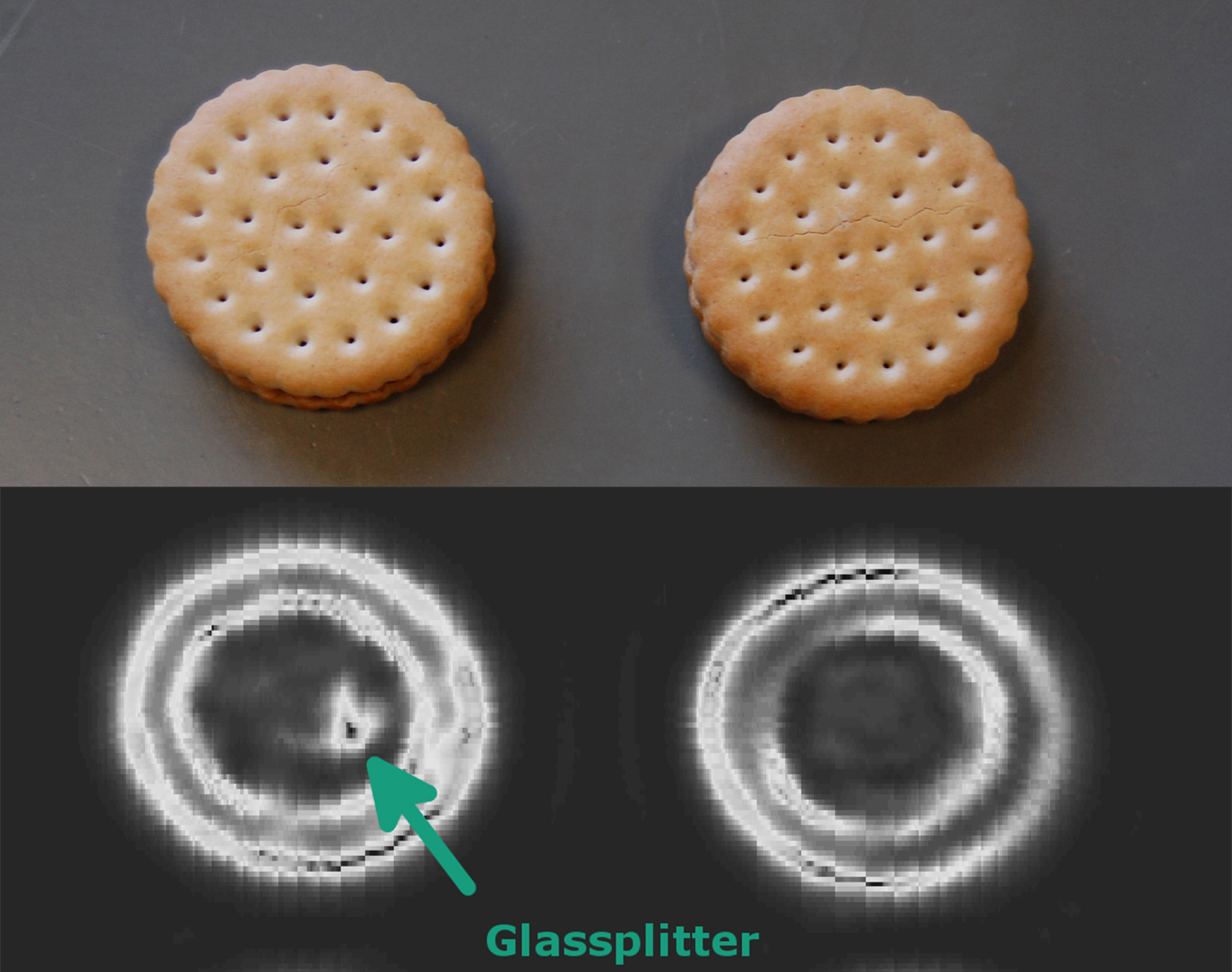

SAMMI® Recognizes Glass Fragments

A prototype called SAMMI® has been developed at Fraunhofer FHR. The system involves placing the food to be inspected on a conveyor belt and passing it through the device. The transmitting antenna rotates above the belt, the receiving antenna below. The device has a size of 40 x 40 x 30 centimeters and allows for the inspection of food with a size of up to 30 x 30 x 5 centimeters. From a purely technological standpoint, however, there is no limit. The first feasibility studies have already been completed. A glass fragment for example, was placed into the chocolate cream of a sandwich cookie and was reliably detected. An Advent calendar was also inspected successfully: The radar image clearly showed that three pieces of chocolate were missing while all others were there and correctly positioned. A next step will now aim to further improve the inspection speed and the accuracy.

The technology is not only suitable for food control. Another area for which the system offers advantages is non-destructive product testing: In the examination of an Advent calendar, for example, it can reveal whether the adhesive has been applied with sufficient thickness at the adhesive points where the calendar is held together. The system of the company Hübner Photonics is already being marketed for the inspection of letters and smaller packages under the name T-SENSE®.