Know-how from a single source

Together we are stronger - this also applies to the Fraunhofer Groups. In the Fraunhofer Group for Microelectronics, 16 Fraunhofer Institutes pool their expertise - Fraunhofer FHR also contributes its know-how.

The Fraunhofer Group for Microelectronics (VµE) is one of the nine research groups of the Fraunhofer-Gesellschaft and currently consists of eleven full members and five guest institutes from other Fraunhofer Groups. The Alliance spokesperson is Prof. Albert Heuberger, Institute Director of Fraunhofer IIS. Prof. Heberling is the representative of Fraunhofer FHR in the VµE.

Since April 2017, eleven Fraunhofer institutes in the Microelectronics Alliance have also been working together with the two Leibniz institutes FBH and IHP as the »Research Fab Microelectronics Germany«, or FMD for short.

Three dimensions: Internal representation, external representation and mutual support

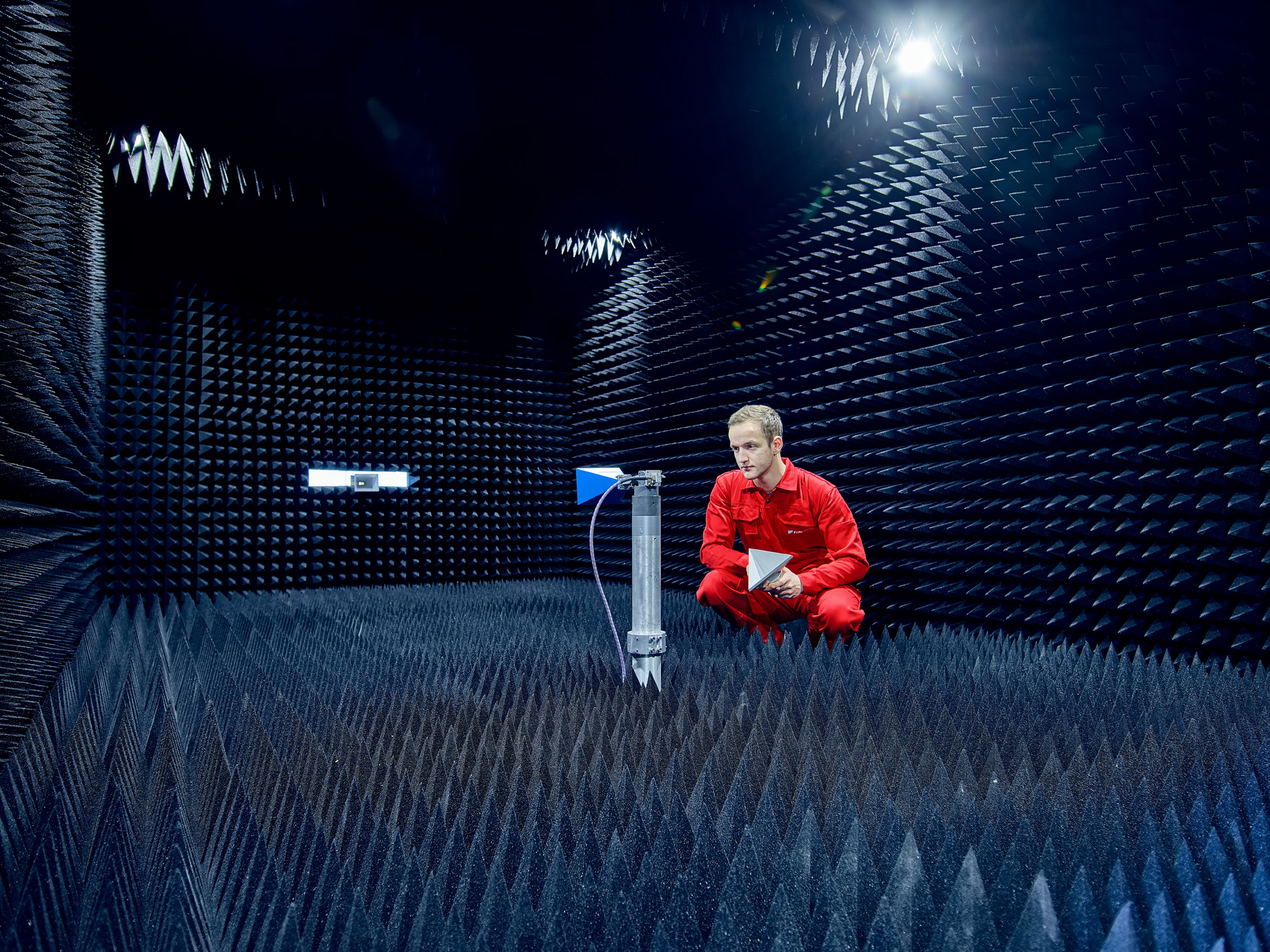

The alliance is a network within the Fraunhofer-Gesellschaft that serves three dimensions: internal political representation, external representation and mutual support. As far as the internal representation is concerned, the VµE represents the microelectronics institutes and their needs towards the Fraunhofer-Gesellschaft, e.g. clean room technology, investment or energy requirements. Furthermore, the group also acts externally vis-à-vis politics and industry. Here, the focus is primarily on the independence of supply chains, after all, microelectronics is a key technology. Thus, the VµE also has a great importance in the external area by carrying the thematic focal points of the network to the outside.

The third pillar is the mutual support of the Fraunhofer institutes in the group: After all, it bundles the competences of all Fraunhofer institutes dealing with microelectronics. Thus, Fraunhofer FHR has very close contact to the semiconductor institutes and their technology lines via the alliance - which is particularly important in the context of research funding. After all, the aim of the alliance is to offer joint research and funding projects for industry, but also to facilitate larger research programs. These are largely not in the field of radar, one of Fraunhofer FHR‘s core competencies, but primarily in high-frequency technology, such as communications or quantum electronics. Fraunhofer FHR would find it much more difficult to enter such programs on its own. The Microelectronics Alliance as a large partner significantly increases the clout - after all, it makes a difference whether a single institute with 250 researchers appears or an alliance comprising about 3000 employees.

Research Fab Microelectronics Germany: One-stop store for external partners

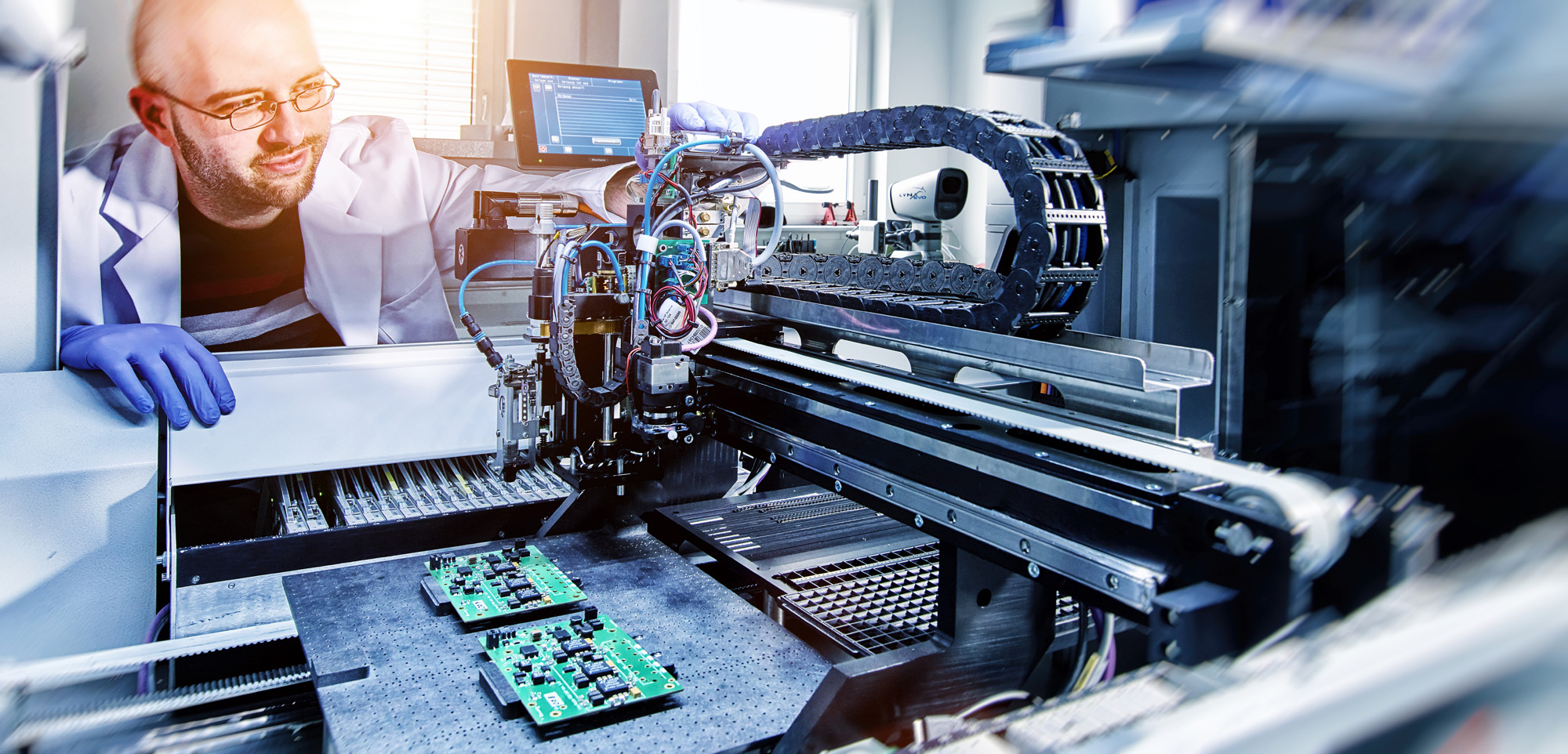

FMD is the central point of contact for all issues relating to microelectronics and nanoelectronics in Germany and Europe. As a pioneer for cross-site and cross-technology collaboration, FMD addresses current and future challenges in electronics research and provides important impetus for the development of elementary innovations for the world of tomorrow. With more than 4,500 employees, FMD is one of the largest research and development associations of its kind.

As a one-stop store, FMD combines the scientifically excellent technologies, applications and system solutions of the cooperating institutes into a combined overall offering in the field of micro- and nanoelectronics. For example, many companies are unsure which is the right semiconductor technology for their application: the silicon technology used in computers and smartphones, the silicon-germanium technology used in the automotive sector, or the III-V semiconductors that are elementary for power amplification, among other things? This is where FMD offers external partners the necessary support and brings together the excellent individual competencies of its member institutes to create a holistic offering. With this cross-institutional bundling of know-how, the entire value chain can be served. As a one-stop store, FMD is thus the central point of contact for cooperation and industry inquiries. Research from a single source, in other words.