Recycling plastics: Via MIMO sensor technology

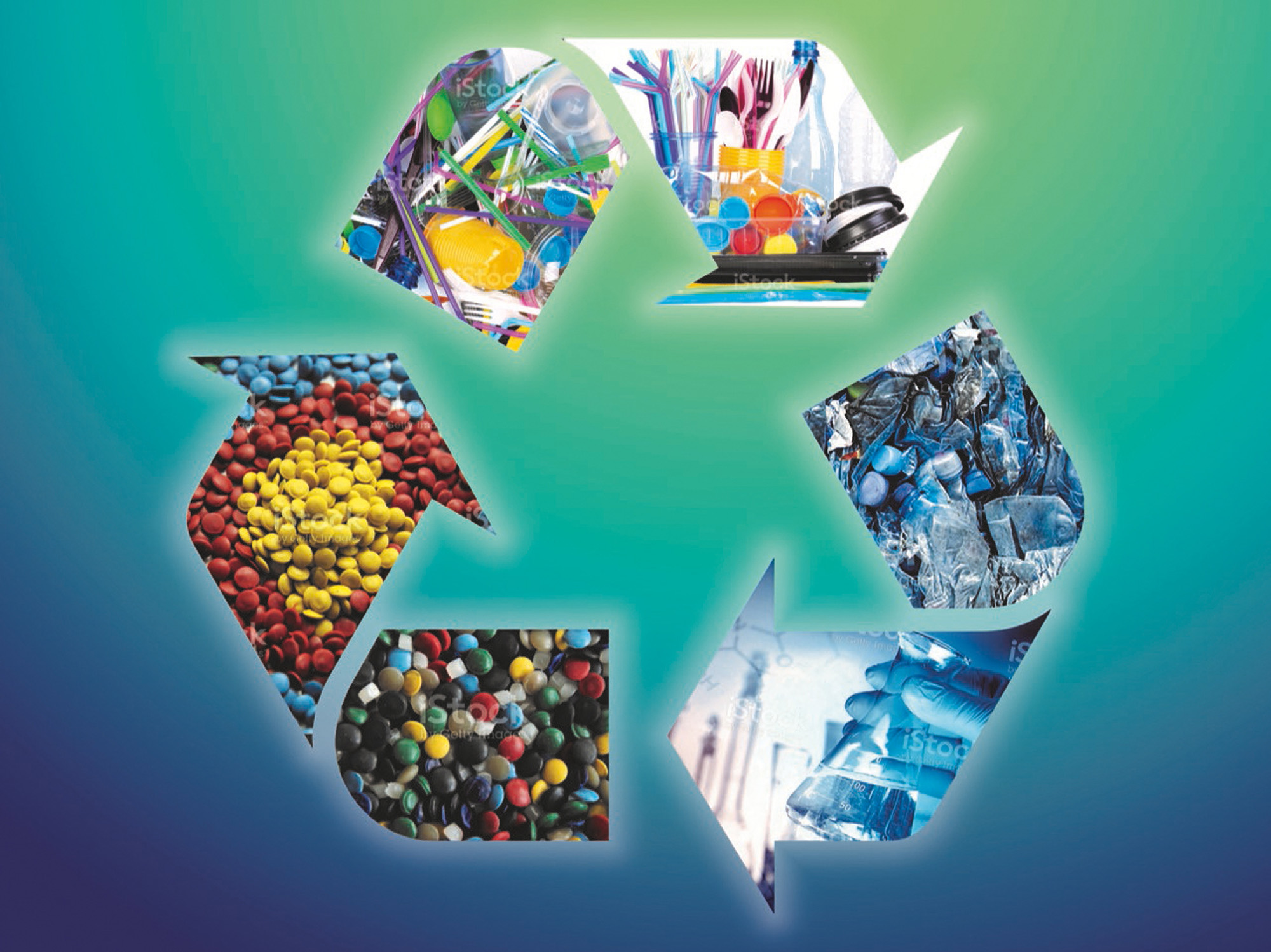

Plastics contain a lot of carbon, but currently only about a quarter of it is kept in the cycle. In the Waste4Future project, seven Fraunhofer institutes are working on technologies to boost the recycling of plastics.

The numbers are staggering: 12 million tons of plastic are consumed in Germany every year, produced almost always from fossil raw materials. Their production releases around 49 megatons of carbon dioxide into the air. Only just under half of the waste containing plastic – 6.3 million metric tons annually – is materially recycled; 53 percent is incinerated. Yet the carbon contained in plastic is an important resource for the chemical industry.

In the Fraunhofer lead project Waste4Future, researchers from Fraunhofer FHR are working with six other Fraunhofer institutes to keep plastics and carbon in the cycle as much as possible and to increase the industry’s security of supply with sustainable platform chemicals. In other words, to be able to increase recycling in the long term. At the same time, this reduces the need for fossil resources, CO2 emissions and plastic waste pollution. The principle: A new type of sorting system identifies which materials and, in particular, which plastic fractions are contained in the waste. Which path makes the most sense technologically, ecologically and economically for which waste?

To this end, Fraunhofer FHR is developing a scalable MIMO radar sensor that includes 32 channels and operates in the G band. It is designed to characterize the waste that passes under it on a belt. Since it is to be a dual-band sensor in the final stage of development, it will not only transmit frequencies from 120 to 160 gigahertz, for example, but also frequencies from 220 to 260 gigahertz simultaneoulsy. In this way, it generates added value about the structure and properties of the material stream. For example, it should not only be able to analyze black plastics, but also enable statements to be made about the aging state of the plastics. The data collected is analyzed by Fraunhofer IZFP using appropriate signal processing and machine learning. The silicon germanium chip for the MIMO sensor is also being developed at Fraunhofer FHR. The challenge here is that it must function not only in one, but in two frequency bands. To do this, an onboard chip antenna for higher frequencies and an external antenna must be combined – due to the spatial distance between the two antennas, this is a complex task both technologically and algorithmically. The developed methods are interesting not only for the chemical and plastics processing industries, but also for companies in waste management, recycling plant construction and recycling plant operation.