Production

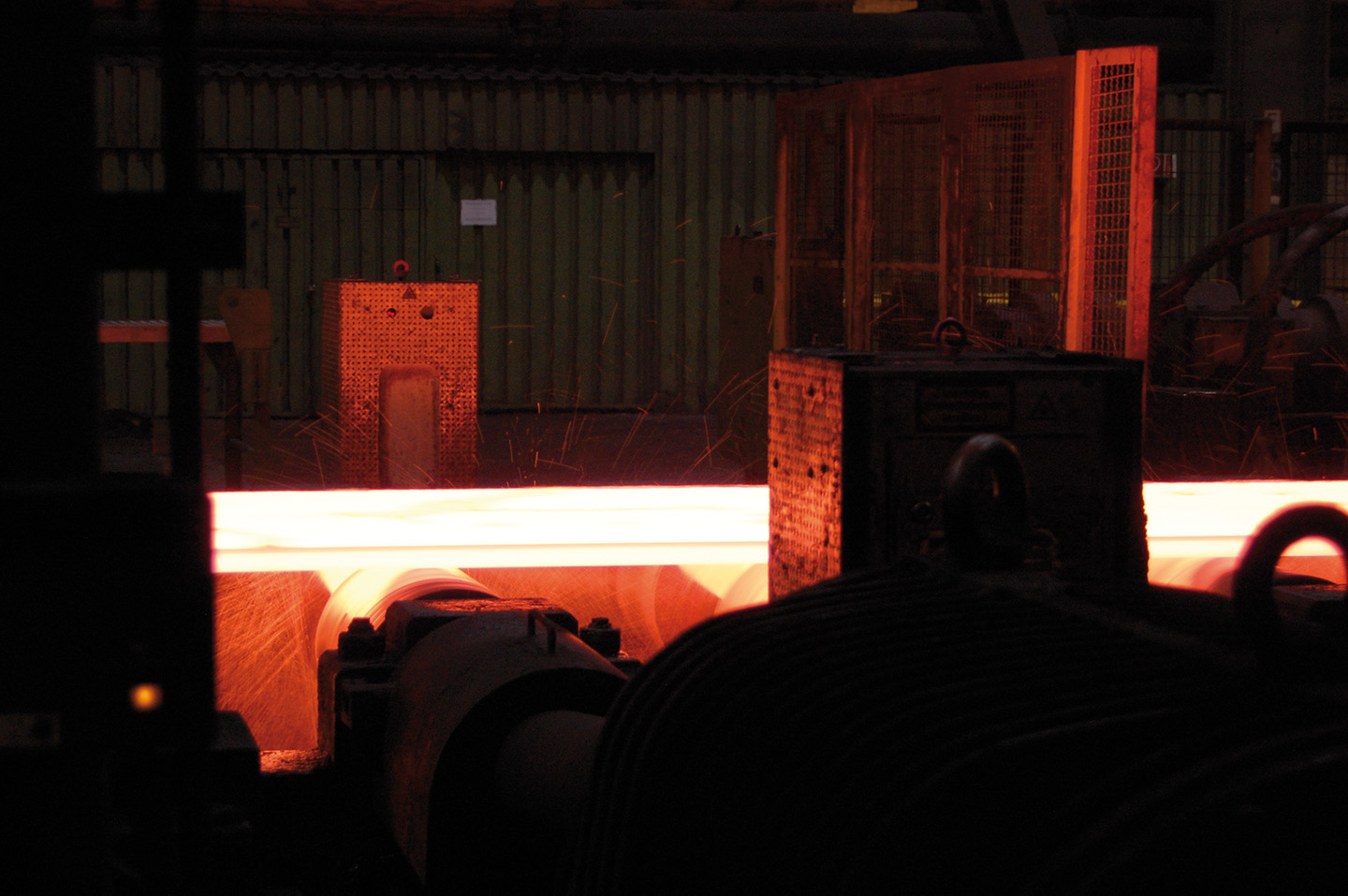

ASRA - Adaptive control of steel strips in hot rolling mills based on high-precision radar signal processing

North Rhine-Westphalia (NRW) is internationally known for its steel production. In order to sustainably increase production efficiency, IMS Messsysteme GmbH, SMS Group GmbH, IMST GmbH, Ruhr-Universität Bochum and Fraunhofer FHR are cooperating within the "ASRA" project to implement using radar methods to measure the contour of the edge of the rolling stock within a hot rolling mill for the first time. Variable edge shapes, ski formation as well as the detection of the rolling stock head and rolling stock foot and speed measurement enable high energy and cost savings due to significantly reduced scrap thanks to real-time control.

The ASRA project is the first to develop a radar method for contour measurement of the edge of the rolling stock in the roughing stand of a hot rolling mill. In this way, an accurate and stable width measurement is to be achieved over the entire length of the rolling stock, even with ski formation (bending of the leading edge of the rolling stock) and variable edge shapes. In combination with speed measurement and an exact detection of the rolling stock head and foot, a width regulation at the rolling stock ends (short stroke control) is made possible for the first time, adapted to the current rolling stock parameters. The area of the rolling stock, which falls below the nominal width and has to be removed, is thus reduced and enables high energy and cost savings due to the significantly lower scrap.

Conventional measuring systems, such as optical and radiometric, have already been tested but could not be operated stably due to the harsh installation conditions. As part of the project, a high-resolution modular and fully integrated multi-channel radar system is being developed, which enables adaptive real-time control from the rolls of the roughing stand. In addition to optimized control algorithms, which for the first time are based on real measurement data, high-resolution radar signal processing methods are designed and implemented within an FPGA for real-time processing.

The ASRA project uses the SiGe-Chip technology of the Ruhr University Bochum, the algorithms / radar expertise and real-time signal processing competence of Fraunhofer FHR as well as the expertise of the IMST for electromagnetic simulation and the production of complex integrated antenna structures and lenses for the implementation of the high-resolution sensor module. Thanks to the experience of the SMS Group in the area of rolling process modeling and control and the IMS measuring systems in the manufacture and integration of different measuring systems in hot rolling mills, the demonstrator developed here can be integrated and tested in a realistic test scenario.