Metal-coated radar antenna from the 3D printer

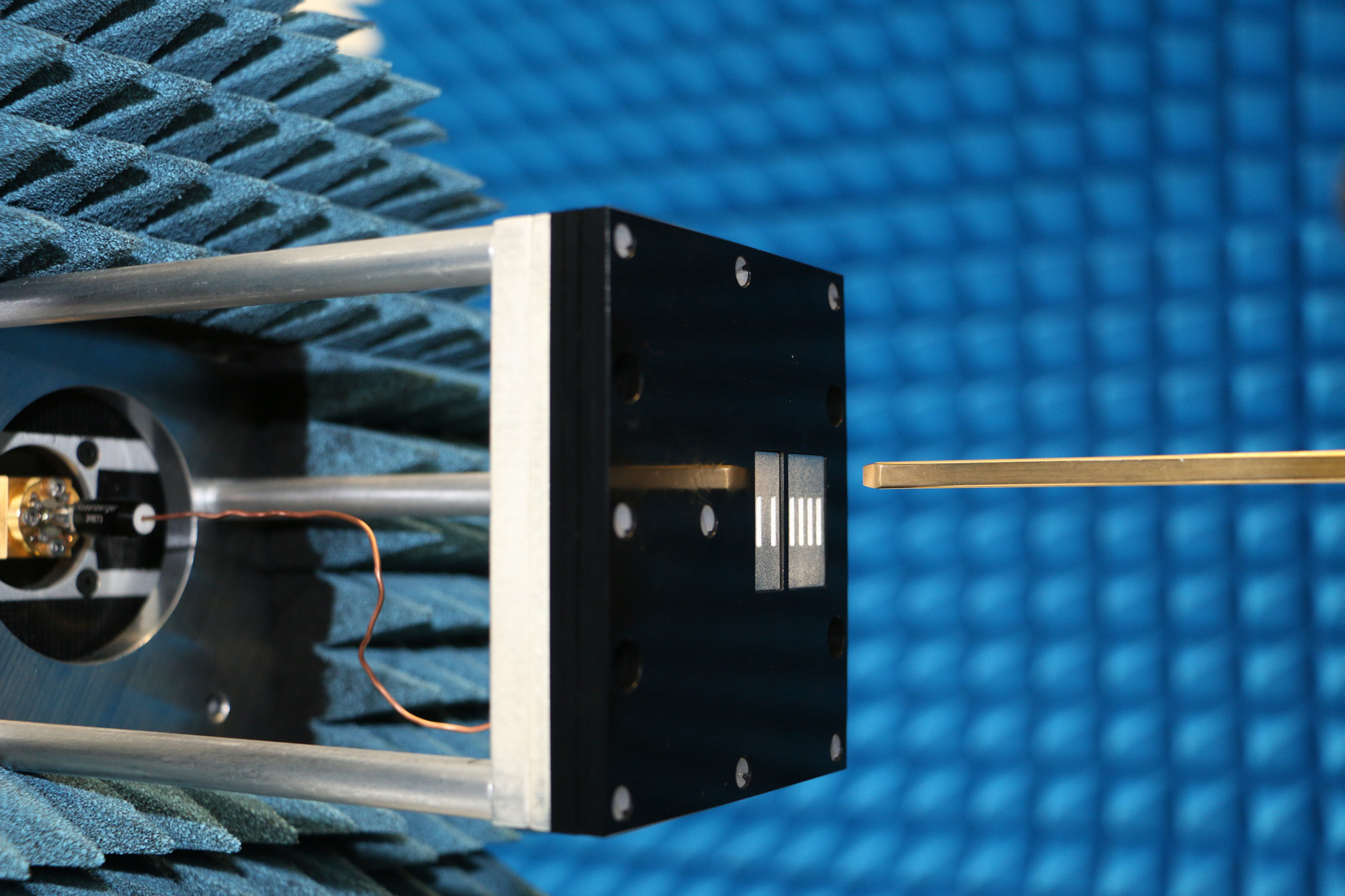

Motorized vehicles can use radar systems to detect what is happening all around them. Now state-of-the-art antenna prototypes for these systems can be produced inexpensively: via 3D printing and metal coating.

While people have eyes and ears to keep an eye on their surroundings while driving and reliably detect pedestrians, cyclists and the like, autonomous vehicles and driver assistance systems rely on sensors. For example, radar sensors, which are already installed in many cars. At least four antennas are usually required for this purpose, one transmitting and three receiving antennas. The transmitting antenna sends radar beams into its surroundings, which are reflected by various objects such as pedestrians, cyclists, cars or lampposts and deflected back to the receiving antennas. With just one receiving antenna, it is possible to calculate the distance and speed of the object. With the second, a rough angular range is obtained in which the object is located - for example, at an angle of about 30 degrees to the sensor. And with the third antenna, this angular range can be narrowed down even further. In general, the more receiving antennas, the higher the resolution and the more objects can be detected simultaneously.

However, with printed microstrip antennas, losses increase when multiple antennas are used, and their bandwidth is also severely limited. Waveguide antennas are different: They are perfectly suited for multi-antenna use. However, there is another problem here. This is because waveguide antennas are usually made entirely of metal, and in many cases they are manufactured from a solid metal block - a complicated, lengthy and expensive undertaking.

Plastic printing instead of metal processing

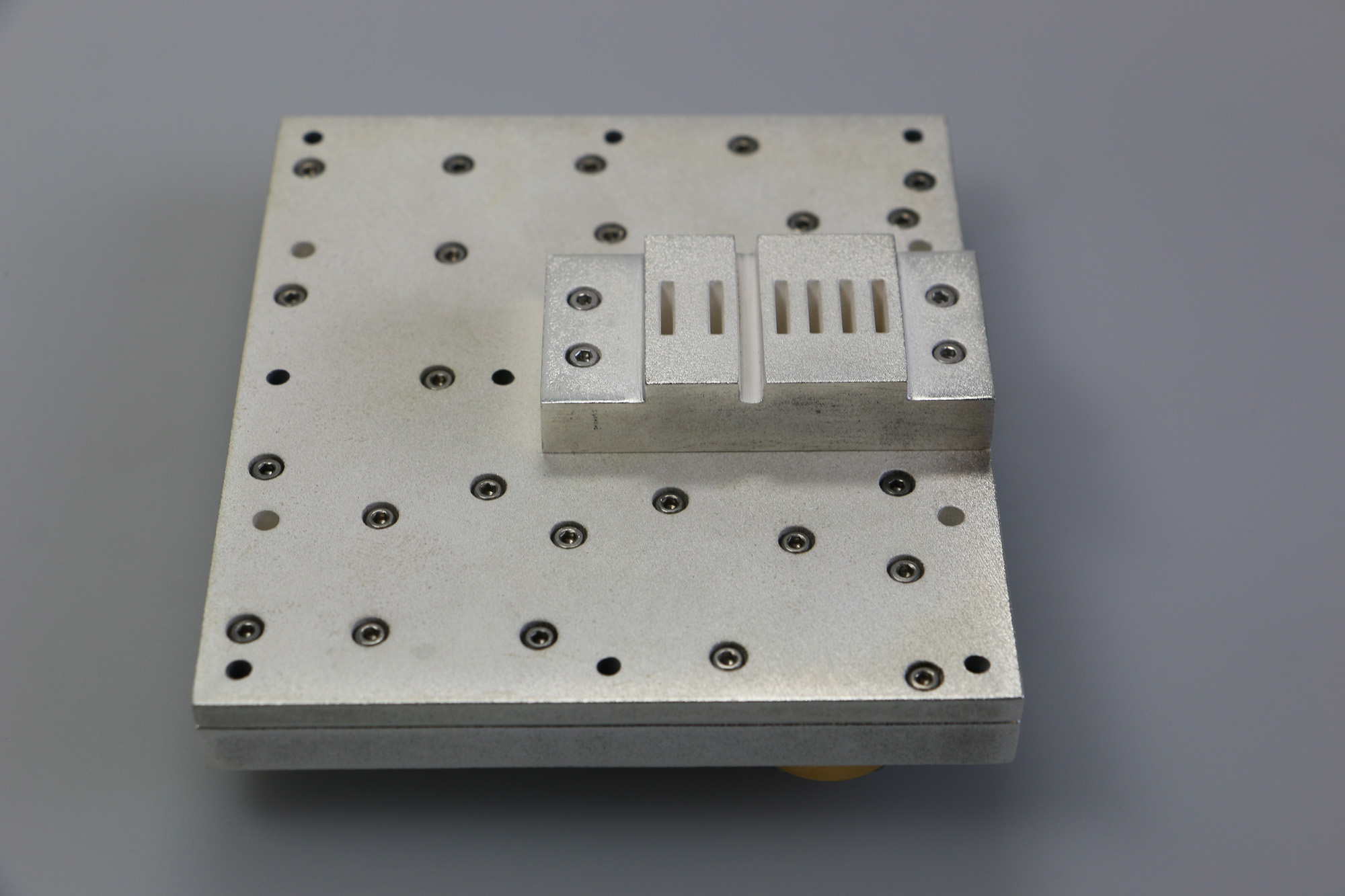

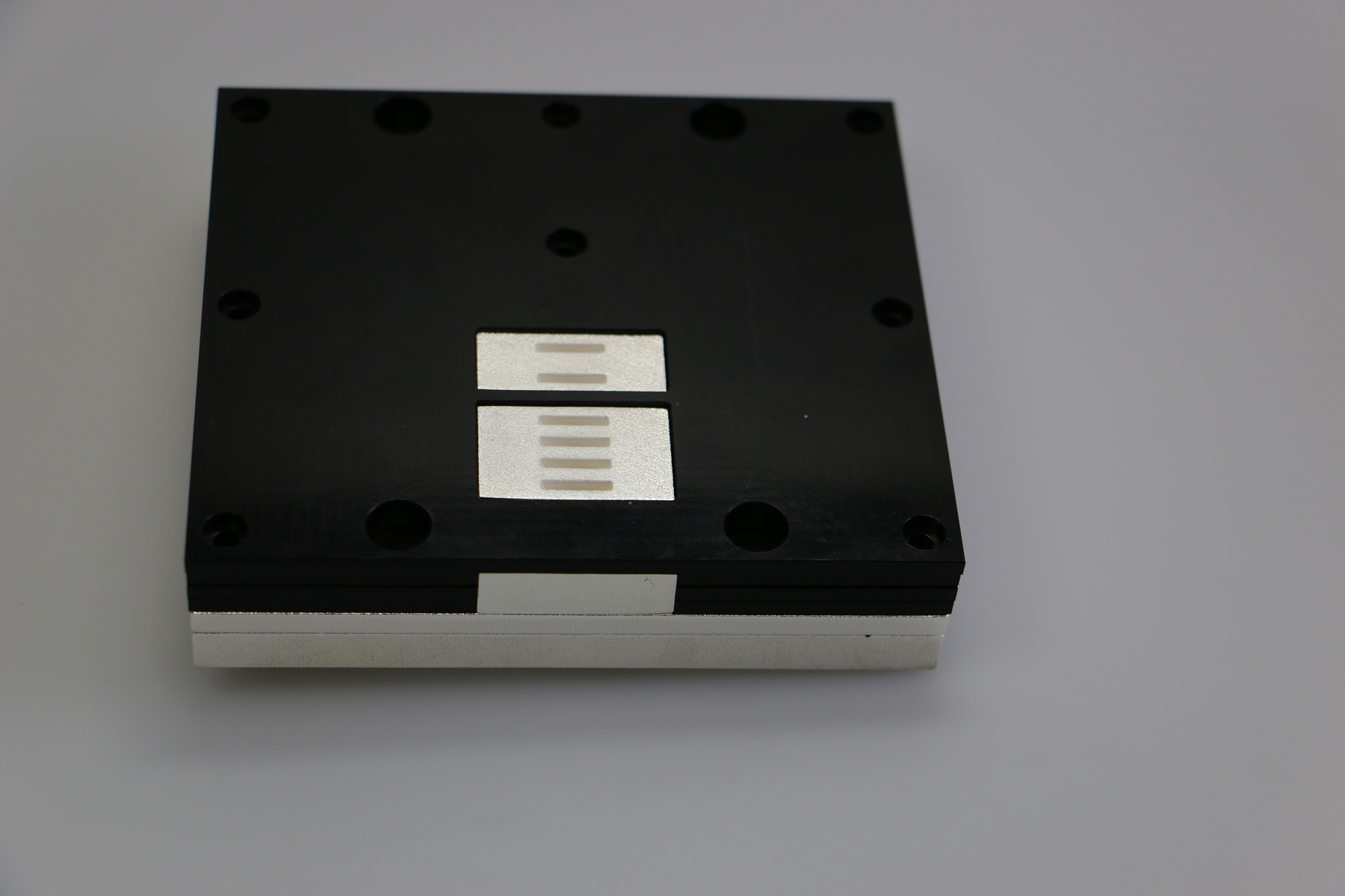

Researchers at Fraunhofer FHR have now investigated a much more cost-effective alternative. Instead of milling the antenna from a metal block, the researchers print it from plastic using a 3D printer and then coat it with metal. To coat the internal cavities, they resort to a trick: Instead of producing the antenna in one go, they divide it into two halves - each of which also contains only half of the waveguide. These halves are coated with metal and then joined together to form a whole. The researchers compared the antenna produced in this way, printed according to Fraunhofer specifications and coated by cooperation partner Biconex GmbH, with metal antennas of identical construction. The results are impressive. The 3D-printed and coated antennas work slightly differently, but similarly well as the metal antennas - and in the entire frequency range from 67 to 81 gigahertz. So they work in both the long-range and short-range. Now, 3D printing offers great flexibility, but it‘s not particularly suitable for mass production. But the researchers have a solution here, too: the two halves of the antenna can be produced just as well via the mass production process of injection molding.