Metamaterials optimize magnetic resonance imaging

Magnetic Resonance Imaging (MRI) has to date been difficult to combine with other diagnostic methods. This is because the strong high-frequency fields in MRI induce sheath currents on the cables of added devices. Now, MRI-compatible, compact sheath current suppressors based on metamaterial technology from Fraunhofer FHR significantly simplify this. Furthermore, smart metamaterial plates result in a far higher signal-to-noise ratio in MRI: The detection of fine structures is significantly enhanced.

MRI has become an indispensable part of medical diagnostics. Among other things, it allows the brain and spinal cord, as well as internal organs, muscles and joints to be imaged layer by layer and examined non-invasively. But sometimes making a correct diagnosis is not enough – a combination of different diagnostic procedures is required. However, this presents challenges: The MRI's strong high-frequency fields induced into the cables of additional devices, be they ultrasound equipment, monitors or similar devices, can interfere with the measurements. Heat can also be generated at the cables’ shields by the induced currents to the point that they can cause burns in patients. Therefore, it is essential to suppress the induced sheath currents. This is typically done using current chokes. These are based on winding up the leads in order to realize the highest possible impedance for the sheath currents. However, this approach is too bulky and requires more space and long leads. Other solutions are based on ferrite beads that can be attached to the respective cable by means, e.g. of a snap lock. Nevertheless, due to the magnetic nature of such components, they are not suitable for use in MRI.

Sheath current suppressors for MRI

Together with the Fraunhofer Institute for Digital Medicine MEVIS, Fraunhofer FHR has now developed a convenient and practical solution to this problem in an internal project. Either sheath current suppressors are attached only at some points of the cable, or the entire cable is covered with a mantle formed by a multitude of sheath current suppressors. The technology, which is currently being patented, is based on metamaterial technology. These are not materials in the usual sense, but artificial entities that have been given a special structure and behavior. Since MRI scanners operate at various frequencies depending on the design and manufacturer, various sheath current suppressors designs have been developed: For 1.5, 3 and 7 Tesla devices. The sheath current suppressors are compact, tunable and reusable. They also preserve the cable's flexible properties. They can be detached from one cable and attached to another. Furthermore, the cables can be equipped with several different sheath current suppressors at the same time allowing for multiple frequencies and broad bandwidth use. For example, a sheath current suppressor solution for 1.5, 3 as well as for 7 Tesla can be attached to the same cable.

Various sheath current barriers have already been characterized in Fraunhofer MEVIS’ research MRI scanner and their functionality has been successfully proven. Fraunhofer FHR also has at its disposal appropriate on-bench measurement equipment, including two coils with which the sheath currents can be specifically generated and measured. Up to now, the sheath current barriers have been manufactured using conventional production methods. However, new manufacturing technologies are now being used such as 3D printing technology, i.e. additive manufacturing, which is also possible at Fraunhofer FHR. This provides a cost-effective and at the same time high-performance solution.

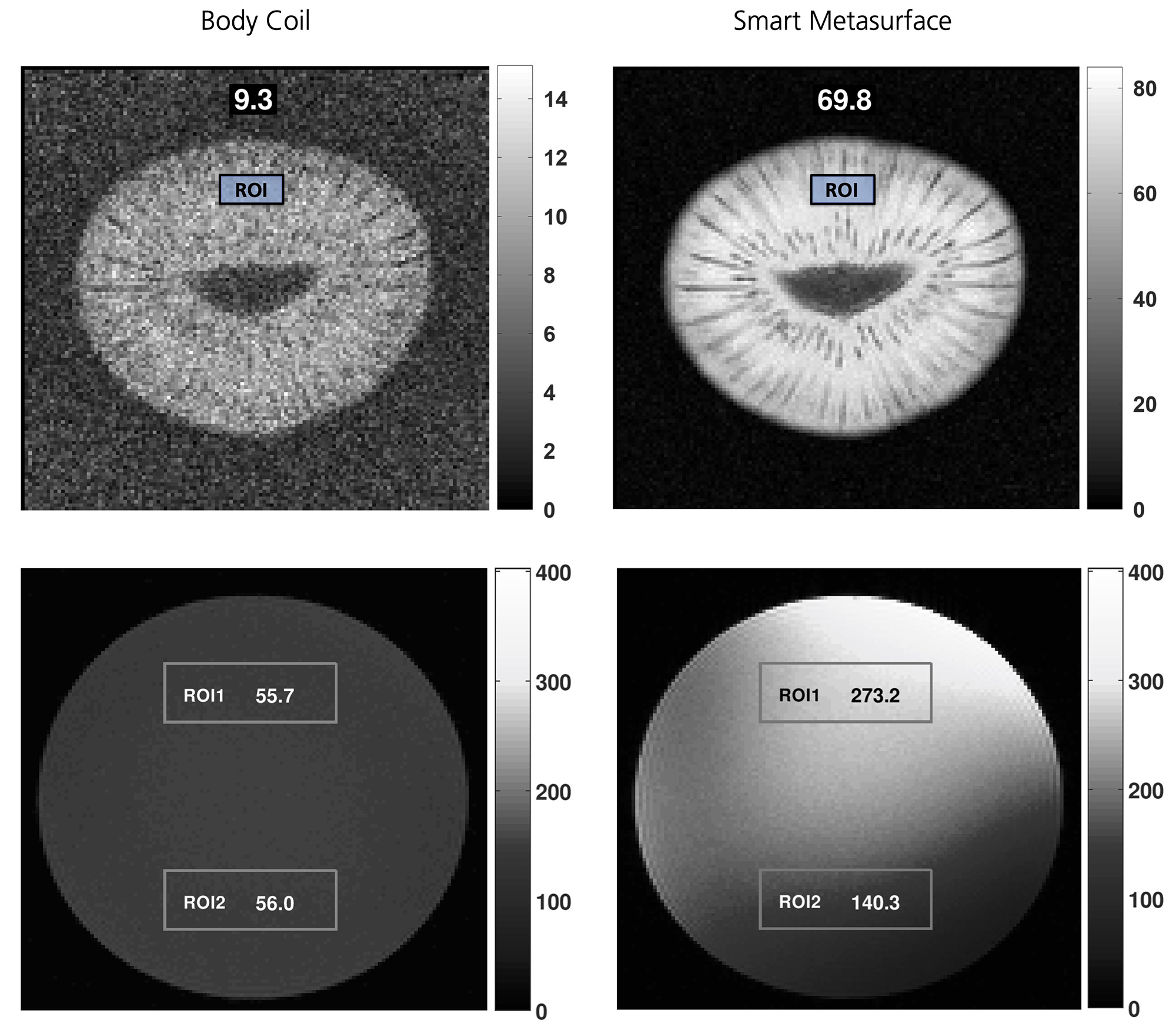

Metamaterials improve measurement sensitivity by a factor of five

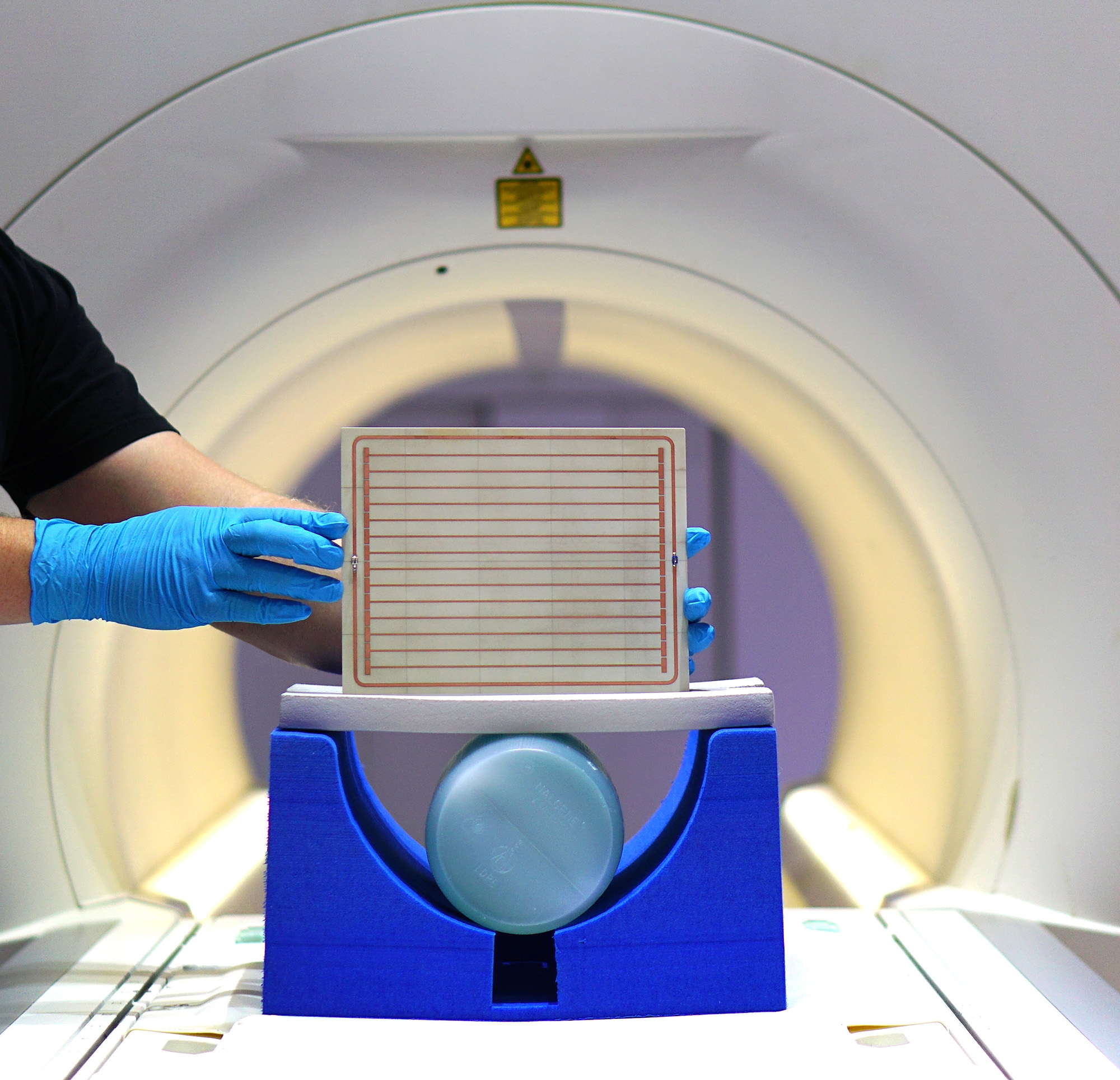

Metamaterial devices also offer many advantages and opportunities in improving MRI images themselves. Among other things, they can significantly improve measurement efficiency: If the scan is carried out using surface coils placed close to the patient's body, the signal-to-noise ratio (SNR) can be improved by up to 20 percent, depending on the region to be imaged. If the coils permanently installed in the MRI scanner, the so-called body coils, are used, the SNR can be increased as much as fivefold. Fine structures are thus much more easily-identifiable on the images as the contrast increases considerably. This great leap in measurement efficiency is enabled by smart metamaterial plates, which are placed on the part of the body to be examined during the MRI scan. Various metasurface plates have already been tested in the Fraunhofer MEVIS MRI research lab and their enhancing effect has been successfully demonstrated.