Cutting-edge radar sensor technology successfully tested

New sensor for contactless quality control in the industrial production of metal webs now on the market.

Maxcess, a leading provider of innovative products and services for web handling ap-plications, has collaborated with Fraunhofer FHR to develop a new radar sensor to enhance web production in the metal industry. Maxcess introduced the prototype of the new Fife ExactTrak Radar Sensor at last year's METEC trade fair in Düsseldorf. Its practicality was demonstrated in a comprehensive 12-month field test phase at Ségal in Belgium. The newly available sensor utilizes radar waves to accurately detect the position of a metal strip through the insulation window of an oven with temperatures exceeding 1000°C.

"We are delighted to have partnered with the Fraunhofer FHR, a well-respected research organization known for their rich experience and commitment to innovation," says Dr. Paul-Philipp Zänker, Research and Development Manager for Maxcess Europe. "The introduction of radar technology marks a significant milestone in our company's history, and we are excited to introduce it to the market."In contrast to existing radar sensors, Maxcess's Fife ExactTrak Sensor offers significantly improved accuracy. This performance reduces waste and scrap significantly, aiding industries in optimizing their processes and achieving a more efficient and sustainable solution.

About the new Fife ExactTrak Radar Sensor

This new radar sensor is used in treatment lines in industrial production for contactless detection of the center position of metal strips. lt is an alternative to the well-known capacitive or inductive strip center sensors used today in continuous process furnaces. The conversion from existing sensors to the new radar sensor is fast and easy. Its main benefits are a completely maintenance free system, enhanced operational reliability, high precision, easy installation, and an insensitivity to pollutions of all kinds.

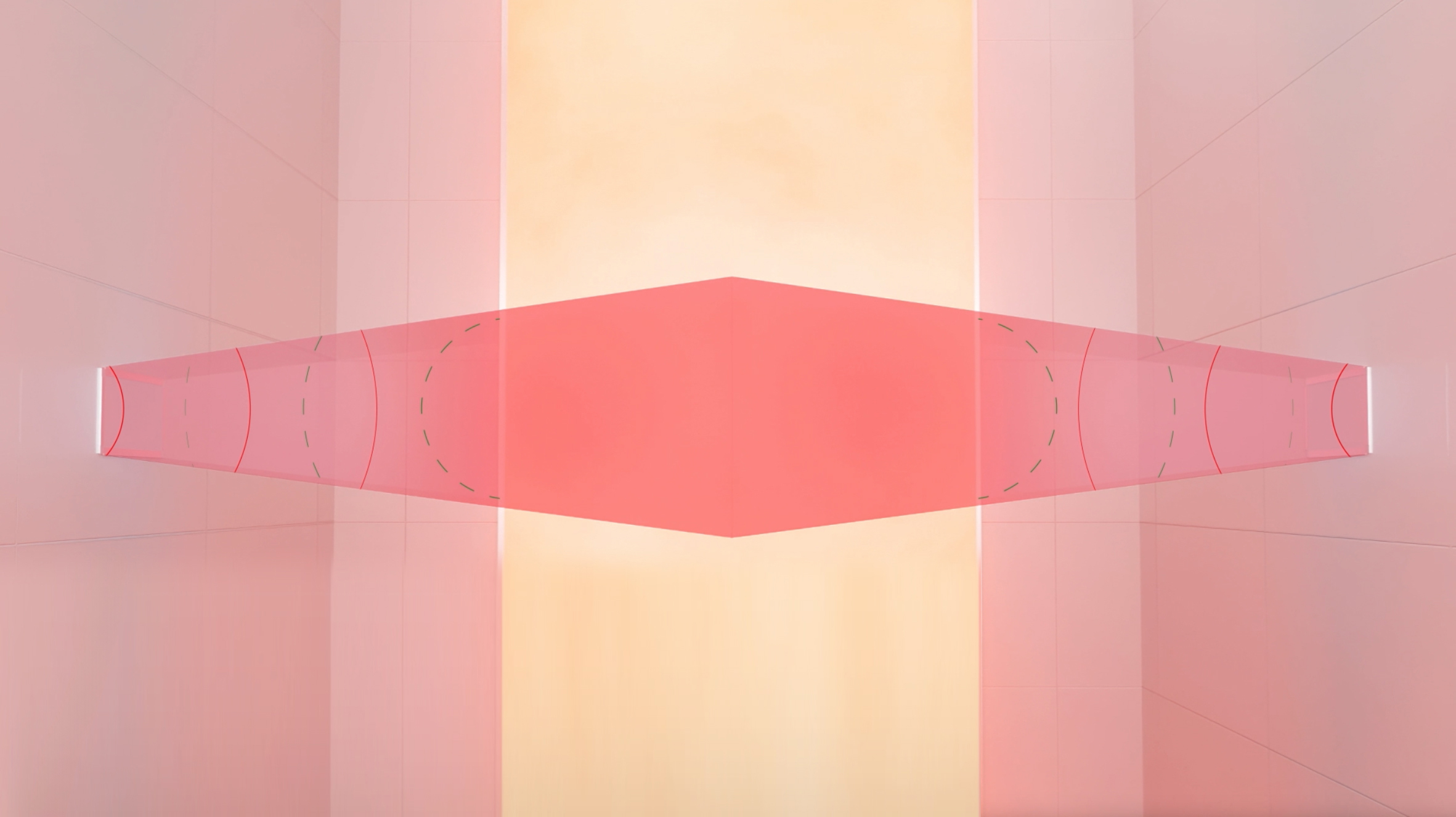

A system consists of two radar measurement devices on each side of the furnace detecting the position of the metal strip through the thermal insulation from the outside. The transmitting antenna emits electromagnetic radar waves, through the furnace window onto the side of the metal strip. The reflections from the side of the strip are picked up by the receiver antennas. By evaluating the time taken for the radar wave to return, the position of the metal strip is determined. The strip's center position is calculated from both distance values and controls in real time the position of the strip.

About Maxcess

Maxcess helps its customers maximize productivity through innovative and sustainable products and services worldwide. By combining more than 400 years of global service and support across the storied product brands of RotoMetrics, Fife, Tidland, MAGPOWR, Webex, Valley Roller and Componex, Maxcess offers an unrivaled network of application experts and end-to-end web handling solutions to help you work better, faster and smarter.

About Fraunhofer FHR

The Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR is one of the leading European research institutes in the field of high frequency and radar technology. The institute develops tailor-made concepts, processes and systems for electromagnetic sensor technology for its partners. With a budget of about 44.6 million euros in 2022 and about 390 employees, Fraunhofer FHR is one of the largest radar research institutes in Europe. The institute is part of the Fraunhofer-Gesellschaft, the world's leading organization for application-oriented research with currently 76 institutes and research facilities, a budget of 3.0 billion euros and more than 30,000 employees.

https://www.fhr.fraunhofer.de/en/sections/Industrial-High-Frequency-Systems-IHS.html

What is "Web Handling"?

"Web Handling" refers to the precise handling and guiding of continuous material webs, such as paper, films, or textiles, as they pass through machinery. The goal is to streamline the process, maximize speed, and minimize waste and other issues. This practice is employed across various industries, including printing, packaging, and material conversion.