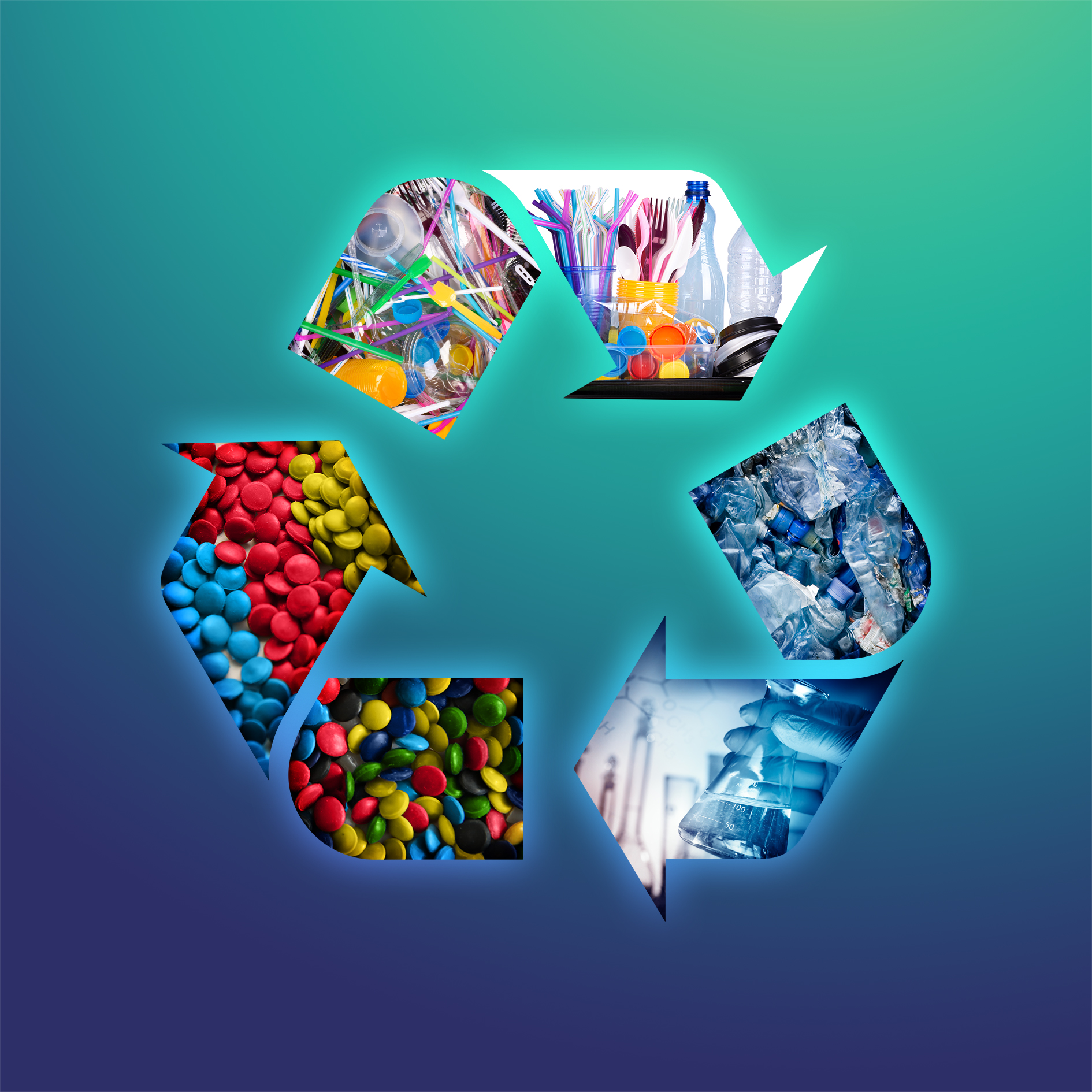

Today's waste becomes tomorrow's resource

"Waste4Future" paves new ways for plastics recycling

A sustainable society with climate-neutral processes requires significant adjustments in the value chains, which are only possible through innovations. Seven Fraunhofer Institutes are pooling their expertise in the lighthouse project "Waste4Future" to develop new solutions for this goal, from the raw material base to material flows and process engineering right to the end of a product's life cycle. In particular, they want to increase energy and resource efficiency in the use of plastics and thus pave the way for a chemical industry that requires fewer fossil raw materials and produces fewer emissions.

Plastics such as polyethylene (PE), polypropylene (PP) or polystyrene (PS), which are currently produced almost entirely from fossil raw materials, are fundamental to many everyday products and modern technologies. The carbon contained in plastics is an important resource for the chemical industry. If it is possible to better identify such carbon-containing components in waste, to recycle them more effectively, and to use them again to produce high-quality raw materials for industry, the carbon can be kept in the cycle. This not only reduces the need for fossil resources, but also pollution with CO2 emissions and plastic waste. At the same time, the security of supply for industry is improved because an additional source of carbon is tapped.

The "Waste4Future" lighthouse project therefore aims to create new opportunities for recycling plastics in order to make the carbon they contain available as a "green" resource for the chemical industry. "We are thus paving the way for a carbon circular economy in which valuable new base molecules are obtained from plastic waste and emissions are largely avoided: Today's waste becomes tomorrow's resource," says Dr.-Ing. Sylvia Schattauer, deputy director of the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, which is heading the project. "With the know-how of the participating institutes, we want to show how the comprehensive recycling of waste containing plastics without loss of carbon is possible and ultimately economical through interlocking, networked processes." The outcome of the project, which will run until the end of 2023, is expected to be innovative recycling technologies for complex waste that can be used to obtain high-quality recyclates.

Waste4Future at Fraunhofer FHR

The Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR in Wachtberg is developing the terahertz sensor technology of the sensor suite for the sorting plants within Waste4Future. Here, the sensor technology is to determine both the material parameters for the purest possible sorting and the aging of the sample. The age of the sample is relevant to assess whether/how it is suitable for chemical recycling, among other things. Both aspects are to be detected with the sensor suite: Optical sensors, thermographic sensors, line lasers and airborne ultrasound are networked here. The collected data will be linked and evaluated using machine learning methods on the part of Fraunhofer IZFP. The sensor suite is mounted above the assembly line of a sorting plant. Compressed air sensors are then used to sort out the unwanted materials. As part of the project, Fraunhofer IOSB and Fraunhofer IWKS are both modifying and developing sorting systems.

Fraunhofer FHR is developing and building a dual-band radar sensor with a silicon germanium-based radar chip that simultaneously emits two frequency bands. These are algorithmically fused by Fraunhofer IZFP. The wide bandwidth allows the parameters of the sample to be captured as well as possible. The system is being built as a line scan camera that will cover 18 cm of conveyor belt in the sorting plant. The modular system is designed to be scalable, so that two modules then cover 36 cm, and so on. The first chip for both frequencies is planned for spring 2022, and the complete assembly stage of the demonstrator should be ready by January 2023.

Joint project of seven Fraunhofer institutes

For the development of the corresponding solutions, the participating institutes are in close exchange with companies from the chemical industry and plastics processing, waste management, recycling plant construction and recycling plant operation, in order to consider the needs of industry in a targeted manner and thus increase the chances of rapid application of the results achieved.

The following Institutes are involved in the Fraunhofer lighthouse project "Waste4Future":

- Fraunhofer Institute for Microstructure of Materials and Systems IMWS (lead)

- Fraunhofer Institute for Non-Destructive Testing IZFP

- Fraunhofer Institute for Materials Recycling and Resource Strategy IWKS

- Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB

- Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR

- Fraunhofer Institute for Structural Durability and System Reliability LBF

- Fraunhofer Institute for Process Engineering and Packaging IVV

- https://www.waste4future.fraunhofer.de/ (waste4future.fraunhofer.de)